How to choose an actuator and properly mount it to the gate?

In order for the automatic gate opening system to function for a long time and failure-free, it is necessary to pay attention to important details. Undoubtedly, it is the selection of the appropriate stroke length of the actuator. The second important thing is the distance of the hinge mounting between the gate wing and the post. The above elements will directly translate into the service life of the actuator used. It is especially important when the door is used in quite difficult conditions. Difficult conditions can be called the case when the gate wings are not very airy, like when the wings are filled with sheet metal or have thickly arranged, wide rails. Such a structure is exposed to severe wind loads.

In the case of a long gate wing or when the gate is not airy, a longer actuator should be used. The larger the wing and the less airy it is, the longer should the actuator be. Moving the hooking point away from the hinge towards the wing end will reduce the force acting on the actuator. It can be a force tearing it or compressing it, when the gate meets high resistance to movement, e.g. strong wind.

The weight of the gate wing itself is also very important when selecting the actuator. This is important because it directly translates into the inertia of the gate. Inertia, in turn, causes the actuator to overload when starting and stopping. The heavier the wing, the greater the inertia, and therefore it requires the use of a stronger and longer actuator.

Extending the actuator is also necessary for a gate with wide posts. In this case, the hinge is at a great distance from the edge of the post to which the actuator mounting is attached. The use of an actuator with a too short extension will prevent the gate from opening to its full width if it is closed, or vice versa – when it is open, it will not fully close.

Additionally, I must mention two significant angles in the geometry of the “post – gate wing – actuator” system. First, there is the opening angle of the gate. The greater this angle, the longer the actuator will have to be used. The second angle is the angle between the longitudinal axis of the actuator and the plane of the gate wing. It is necessary to ensure that the actuator is at the greatest possible angle to the gate in order to maximally improve its working conditions and thus extend its service life. This can sometimes require a longer actuator.

The general principles of selecting a motor for a gate can be written as follows:

- The longer the gate wing, the longer the actuator

- The heavier the gate wing, the longer and stronger the actuator

- The wider the post – the greater the distance from the hinge to the actuator mounting on the post, the longer the actuator

- The greater the opening angle of the gate, the longer the actuator

Therefore, the selection of the actuator for the gate is not very complicated. All you need to do is keep in mind the simple rules I have outlined above. And if you still have doubts about which actuator to choose, follow the rule: “Better more than not enough”. What does it mean? It is always a good idea to take a longer and stronger cylinder so that you have a reserve of power and extension in the cylinder. Better than having the actuator too small and too weak after purchase.

We have also explained the rules for selecting the actuator for a swing gate in our YouTube video:

How to choose the fixing points of the actuator on the gate

Despite the correct selection of the appropriate actuator, the problem may be the correct installation of the actuator on the gate.

But as you know, not every hero wears a cape… :)

That is why I announce to everyone that we have prepared a tool that will select everything for you!

We have created a calculator that selects the optimal mounting points of the actuator on the gate and on the post in such a way that the actuator at a given extension can open the gate to a given angle. At the same time, it ensures that the actuator has the best possible working conditions. It selects the mounting distances so that the actuator is at the greatest possible angle to the gate wing..

The calculator is available online – link here.

How to use our calculator?

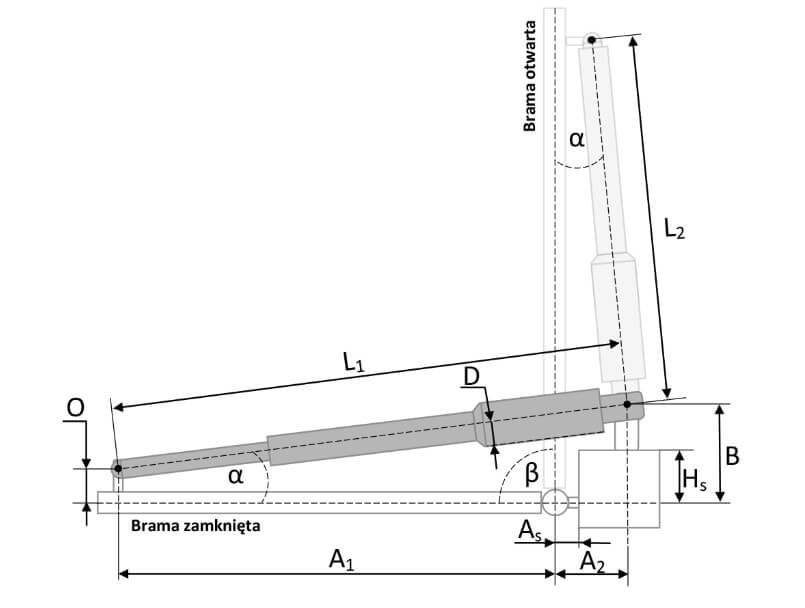

On the calculator page, you will find a simple diagram like the picture below:

On the calculator page, you will find a simple diagram like the picture below:

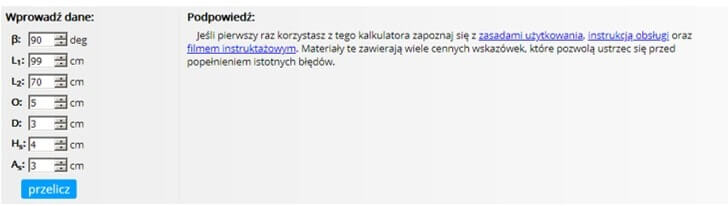

Your task is to provide the following parameters in the form:

- β – door opening angle in degrees

- L1 – length of the unfolded actuator when the gate is closed

- L2 – length of the hidden actuator when the gate is open

- O – shift of the actuator ending on the wing from the wing plane

- D – half the width of the rear of the actuator (at its widest point) – needed to detect the collision point of the actuator with the edge of the post

- HS – distance from the plane side of the closed gate to the side of the post on which the actuator will be mounteddistance from the plane side of the closed gate to the side of the post on which the actuator will be mounted

- AS – distance from the hinge axis to the side of the post to which the hinges are attached.

After entering the parameters, just click the “recalculate” button to get the calculation result on the right side of the form:

The designation of the result parameters can be easily found in the diagram :)

Now all you have to do is measure the distance A1 on the gate from the hinge and screw the mounting of the cylinder end there. Screw the fixing on the post so that the center of the bolthole falls exactly in the point defined by parameters A2 i B.

And that’s it, ready! :)

biuro@elektrobim.pl

biuro@elektrobim.pl 91 817 14 69

91 817 14 69