Actuator mechanics, or how does an electric actuator work?

There is a lot of talk about linear actuators being simple, cheap and safe. However, there is little talk about how they work and what makes the piston move. This technology is constantly evolving, but the principle of operation remains the same.

Today we will answer the basic questions, such as how an electric actuator works, what is its structure and what its applications are.

Types of electric actuators

When we say “electric actuator” we most often mean a piston linear actuator in which one part extends from the other. But it turns out that these are not the only electric actuators that can be found on the market. So let’s make some basic division.

The basic group of electric actuators are linear actuators, among which the following can be distinguished:

- cylinders with a piston rod in which one part (piston rod) extends from the stationary fixed part:

- with trapezoidal, ball or roller screw

- single-acting (push or pull) or double-acting

- with axial attachments or with rear side attachment

- single or multi-section (telescopic)

- rodless cylinders in which a carriage moves along the propeller, to which the moved element is attached.

In addition, there are also rotary actuators in which the output element rotates instead of extending or retracting. Such actuators are often used with swing gates, on wide posts (they have broken “arms”).

Each of the mentioned groups of actuators can be powered by AC or DC motors. Moreover, the electric actuators can have built-in end contacts or be made without them. They can also be made with feedback (potentiometer, pulse generator) or without these additions.

Construction of a linear piston electric actuator

Simply put, an electric actuator (also known as a linear actuator) consists of a motor and a gear that converts the rotational movement of the rotor into the linear movement of the piston.

In order to be able to achieve sufficiently high forces at the piston tip, multi-stage gears are generally used.

Electric actuators differ significantly from pneumatic or hydraulic actuators. They are not driven by compressed air or oil pumped by a pump, but by electricity. Thanks to this, control and operation of such an actuator are much simpler and cheaper. You do not have to worry about leaks that could occur with a hydraulic or pneumatic cylinder. Such losses could reduce the force of the actuator. Additionally, there is no need to replace expensive pumps or compressors, which wear naturally. The installation controlling the electric actuator is therefore much less complicated, and thus cheaper and easier to install.

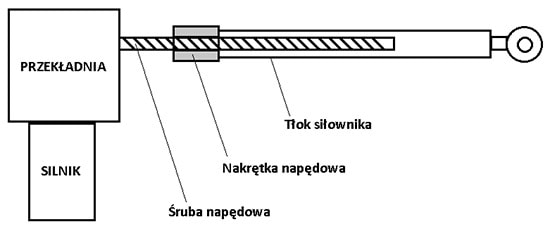

So, what does the mechanics of our actuators look like? It is presented in a simplified way in the figure below. It illustrates the operating principle of electric screw actuators.

The principle of operation of such an actuator is very simple. The electric motor uses the gear to turn the lead screw, along which the nut moves. A piston is attached to the nut. The movement of the nut on the propeller consequently gives the entire piston movement (it extends or retracts into the actuator body). It’s that simple, isn’t it?

Such a construction of the actuator also means that the actuator is able to support the weight placed on it, even when the power is disconnected from it. The multi-stage gearbox, especially the propeller and the nut that moves on it, makes the system “self-locking”. The point is, you cannot push in or pull out the plunger when the engine is not running. Of course, when too much weight is placed on the actuator, the gearbox will “cease to be self-locking” because the actuator will simply be damaged.

Okay, but how does the actuator “know” when to stop?

The actuator stop can always be triggered by disconnecting the power supply from the motor. This is where different paths to the goal emerge.

Some actuators do not have built-in “limit switches” that could disconnect it in the desired positions (for example, ETM-01 i ETM-02 actuators by Elektrobim). Then what? Such actuators are designed to cooperate with the controller, which is equipped with a system for measuring the current flowing through the actuator.

What’s all this for? If the actuator is to operate a hinged gate, it makes quite a lot of sense. The control units are generally equipped with an overload switch. Disconnection of the actuators will take place after the wings rest on the limiters. They are installed in the places where the wings are to stop. The resistance increases the current that flows through the actuator, and this is “sensed” by the controller. Pressing the gate leaves against the resistors does everything together, removing the play space on the gate. And the wings always stop in the same places. Even with time, there is no loss of precision.

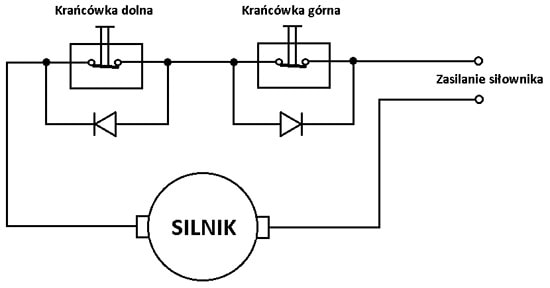

Other actuators may have built-in limit switches hidden inside the actuator. In this case, the signal is not output from the actuator to the control system. And the very “decision” to disconnect the power supply from the motor is carried out by these built-in limit switches. Movement of the piston in the opposite direction will become possible only after reversing the polarity of the actuator supply voltage. Examples of such actuators can be all models from the Power Jack, FDI, NLAD, SL i CAR-2500 series available from Elektrobim.

The simplest form of electrical system looks like the picture below.

You can also find actuators with limit switches, from which the signal is led outside the actuator. It can be connected to the control system. The main difference between this and the previously described case is that in this case the limit switches do not disconnect the voltage from the motor. This task must be performed by the controller itself when it receives a signal from the switches.

Connecting such an actuator is also more complicated. This is because 2-core cables are not enough anymore, but a minimum of 5 are needed (if the switches have one common end).

What if you need to know where the piston is?

No problem! All you need to do is select the appropriate actuator. This may be, for example, one that has a sensor that generates a number of output pulses per travel distance unit of the piston. Elektrobim offers several such actuators. These include actuators from the Power Jack czy FDI series. The disadvantage of such solutions is that you have to calibrate the system each time the power is turned on. This is necessary in order to calculate the position of the piston during operation from its displacement. The sensor output pulses are counted. Inaccuracies may appear if the control system “misses” a pulse.

What if we need to know the position of the piston, and we cannot calibrate the system every time it is turned on? Then the way out of the situation is to use an actuator equipped with a potentiometer or an output encoder.

We have in our company actuators with an output potentiometer. This is the GNT series. The control system should measure the resistance between the potentiometer terminals and on this basis calculate the current position of the piston. This is how we answered the question “How does an electric actuator work”.

All clear, but what can you use electric linear actuators for?

The field to show off is HUGE! The possibilities of using actuators are limited only by our imagination.

Most often, Elektrobim actuators are used to automate swing gates. Do you want to open the gate inwards or outwards? Do you need one leaf to open wider than the other? Do you have narrow posts, or on the contrary – so wide that it’s easier to jump over them than walk around? Our actuators are suitable for EVERY gate without exception! Of course, not every actuator can be attached to any type of post. In our offer, you can choose such actuators or ready-made sets that will perfectly match your gate.

Do you want to automatically open the basement or attic hatch? We recommend FDI actuators, which work extremely quietly and culturally, and will be completely reliable indoors.

We guarantee that you will not put half of the estate on your feet by opening the hatch to the attic, because these actuators you just DO NOT HEAR. They are made very aesthetically, precisely and can transfer loads up to 400 kg.

Are you taking care of a handicapped person who must have an adjustable chair or headboard? Here too, FDI actuators will come in handy. In addition, Elektrobim offers a dedicated controller with a cable remote control, which will make it even easier to build the system.

Electric actuators in vehicles and agricultural machines

Do you have a yacht and want to electrically lift the engine? Nothing simpler, use the CAR-2500 or Power Jack 12V actuator. All you need is a controller with remote controls or a suitable switch and the matter is settled.

Are you a farmer, and you need to make a sprayer boom leveling system or do you want to create a tramline controller on a seeder? Just like on yachts, here you will also need 12V actuators and a simple control system from Elektrobim’s offer. A small “push-button” or a larger two-button switch can perfectly control our actuators. And if you dream of a measure of extravagance, use the controller with a radio remote control.

Do you breed animals? Do you have chickens or some other animals, and you have to release them from the pen every morning and lock them in the evening? I would like to sleep longer, but nothing of it because the zoo is waiting? Now you can sleep well! You just need to use one of our actuators in combination with a timer (we have experience in building such systems). All you need to do is program the opening and closing time of the henhouse door or pen on each of the days of the week and it’s done! Better to sleep longer, because:

“The early bird … Doesn’t sleep in!”

What are some other uses for actuators?

Lifting the flap in the pickup truck? Sun tracking system? A drawer in a desk that opens with a remote control? TV coming out automatically from the wall? A bed automatically hidden in the wardrobe? A window in the hall that opens a few meters above the ground with a remote control? Automatic motorcycle lift? Smoke exhaust flaps? Remote controlled skylights? Advertising board on the hot dog spot folded with an actuator? Seeder path control? Automatic lift for disabled people?

You can do anything you want with our actuators. There are no restrictions on the possible applications. Actuators will take care of the gate that no one wants to open when it rains. You press the button and the gate to the “vault” in your attic will open in front of you. Without getting out of bed, you will let your pets out, open your window, or slide the TV out of the wall…

All this thanks to the wide range of linear screw actuators available from Elektrobim.

Tematy na blogu:

Top 5 korzyści z wykorzystania siłownika elektrycznego

Top 5 korzyści z wykorzystania siłownika elektrycznego

W tym wpisie dowiesz się dlaczego większość inżynierów, jak i zwykłych ludzi, jest bardziej zwrócona w stronę siłowników elektrycznych.

Przeczytaj artykuł na blogu →

Jaki wybrać automat lub napęd do bramy?

Jaki wybrać automat lub napęd do bramy?

Praktyczny poradnik napisany na bazie doświadczeń naszych klientów. Dowiesz się w nim na co zwracać szczególną uwagę podczas zakupu automatu dla Twojej bramy. Przeczytaj artykuł na blogu →

biuro@elektrobim.pl

biuro@elektrobim.pl 91 817 14 69

91 817 14 69

Top 5 korzyści z wykorzystania siłownika elektrycznego

Top 5 korzyści z wykorzystania siłownika elektrycznego