Controlling the gate with a controller – how does it work?

A gate controller or other control unit (or main board) is an electronic control device. It supervises the work of automation executive elements, such as motors and actuators, which set the door in motion.

The driver is also called a controller or a gate control board.

Gate control is most often in the form of a single electronic board. It is integrated with the communication module (e.g. 433.92MHz radio receiver). In addition, it can be integrated with appropriate peripheral systems, depending on the degree of expansion and functionality of a given controller.

Its “brain” is usually a properly programmed microcontroller. Usually manufactured by one of the two companies, ATMEL or Microchip. It is the microcontroller and the quality of the software (so-called firmware) that largely determine the stability of the driver. And stability translates into comfort and safety. Therefore, a very important thing that should be considered when choosing a gate operator is whether it comes from a well-known manufacturer. This ensures that the driver software is at a high level, and the device will not “hang” after some time.

Types of drivers and their purpose:

Controllers can be divided into 3 basic groups, depending on the purpose:

- for sliding gates,

- for swing gates,

- for garage doors.

Despite the considerable differences in application, these devices have many common features. They have very similar functionality. Sometimes to such an extent that, for example, a controller for a sliding gate can be adapted to a swing gate. An example of such a device is e.g. a main board for a sliding gate of the KSE series (photo below):

This controller, despite the fact that it was designed for sliding gates, can also be used to operate a single-leaf gate. The gate must be equipped with a 230V actuator with end contacts led out of it.

Functionality of gate drivers:

1) How does the controller know if the gate is open or closed?

One of the most important things is the functionality of the gate controller. When choosing such a motor, you should first of all consider how it will know about the current position of the gate. How will it know when the gate is fully open or closed?

One of the oldest solutions to inform the controller about the gate position are the so-called limit switches. These are normal mechanical switches. Thanks to appropriate cams or protrusions on the guide, after pressing the micro-switch, they provide information that the controller should complete the work cycle and stop the gate. Magnetic limit switches are used in higher-class machines, such as the KSE series of sliding gate operators. It is definitely a more durable solution than standard mechanical buttons.

In the case of sliding gates, the limit switch module is mounted on the motor. This guarantees simplicity and efficiency of operation. So far, it is the best and failure-free solution to inform the controller about the position of the gate – whether it is open or closed.

Another method of informing the controller about the gate position is the so-called overload module (amperometric protection). It is an electronic module that works with the main microcontroller of the driver board. It is responsible for the continuous measurement of the current flowing through the motor. At the moment of blocking, when e.g. the gate leaf rests on an obstacle or a bumper, it transmits a voltage cut-off signal to the motor.

The overload module is commonly used for swing gates. Its advantage over conventional limit switches is that the wings are always pulled to the stop, and the slack on them is “eliminated”. Each actuator, regardless of the quality of workmanship, has a slight play, which will result in a slight swinging of the wing in the wind.

In the case of sliding gates, the anti-overload system is more of an additional safety device that detects obstacles. Upon encountering an obstacle, the gate moves backwards or stops.

2) How to minimize the danger associated with the operation of an automatic gate?

When installing the drive to the gate, one must not overlook the very important thing that is the safety of the device. Therefore, it should be noted whether the control unit can handle additional accessories. One of such basic safety accessories is a photocell. After all, it is one of the simplest and most effective security measures for an automatic gate. Its main advantage is that it detects obstacles in the gate’s light, even before there is any physical contact between the gate and the obstacle.

The previously mentioned overload switch is the second protection of the drive’s operation. It detects obstacles only after the gate comes into physical contact with the obstacle. If a specific configuration contained only amperometric protection, the car in the driveway could be accidentally scratched.

Do not confuse the overload switch with the overcurrent protection in the power supply. In an overload switch, it is always possible to adjust the pressure. In the case of controllers for double-leaf gates, each actuator is individually adjustable.

3) What if I want to control the drive with an intercom or an additional button

Most professional gate controllers have the option of connecting additional external control signals. Thanks to this, it is possible to connect a simple “bell” button to the drive. This solution makes it possible to control the gate from home. More advanced drivers offer more possibilities. You can connect e.g. additional radio receivers, intercoms, video intercoms, card readers, induction loops, GSM modules, or a control signal from a smart home controller.

Usually, the most useful and most frequently used “control output” is the so-called cyclic work output (sometimes labeled “step by step” output). In this type of solution, the control pulses trigger specific functions one after the other. This is the mode: open-stop-close-stop-open- … etc. It is to the “output of cyclic operation” that standard, wall-mounted bell buttons are connected, which allow the gate to be controlled from home.

Some more complex controllers, apart from the output of cyclic operation, additionally have separate outputs for all functions separately: opening, stop, closing. Separate outputs for individual functions are useful for more advanced solutions. Such examples include intelligent houses or automatically closed entrance gates to large parking lots. Such gates often use RFID card readers or induction loops. An example is the ETM swing gate controller, which, apart from the standard output for cyclic operation, also has the “open” output.

Card readers and induction loops are then connected to the “open” output in the controller. Thanks to this, the gate, after authorization from the RFID card reader, will automatically open, and if the auto-closing function is active, it will close after the set time. Alternatively, the locking signal could be a signal from an induction loop that detects a vehicle exiting the parking lot.

4) Can the gate close automatically?

Most of the controllers available on the market have an auto-closing function. This enables the gate to close automatically after a preset time. This function is always optional, and it is possible to disable it. It is used very often at the entrances to large company car parks, less often on private properties. When deciding to enable this function in the controller, be aware of the potential danger that automatic closing can create. Therefore, it is absolutely recommended to use photocells when the auto-closing function is active. In the case of double-leaf gates, you can consider installing even 2 pairs of photocells. One pair is in the gate’s clearance, and the other, on additional posts, protruding beyond the range of the wings.

5) What about traffic lights?

The controllers have the appropriate outlet for connecting the signaling lamp. This solution is very useful at night, when the operation of the automatic gate may be difficult to see. Every driver will notice the flashing signal light.

When connecting the signal lamp to the controller, make sure that the controller has a built-in circuit breaker. If there is no interrupter on the motherboard, connect lamps with a built-in interrupter. In the case of a controller with a built-in circuit breaker, you can even connect an ordinary light bulb. However, you should pay attention to what voltage will be supplied to the beacon. It can be direct as well as alternating voltage, e.g. 12V, 24V or 230V.

What is the most important for gate drivers?

In short, it can be assumed that regardless of the type of gate for which the device is selected, a high-class gate controller should have such functions as:

- soft start,

- adjustable overload switch (for each actuator separately in the case of double-leaf gates)

- output for external control (at least cyclical operation),

- photocell output.

Zobacz nasze sterowniki do bram w ofercie

Tematy na blogu:

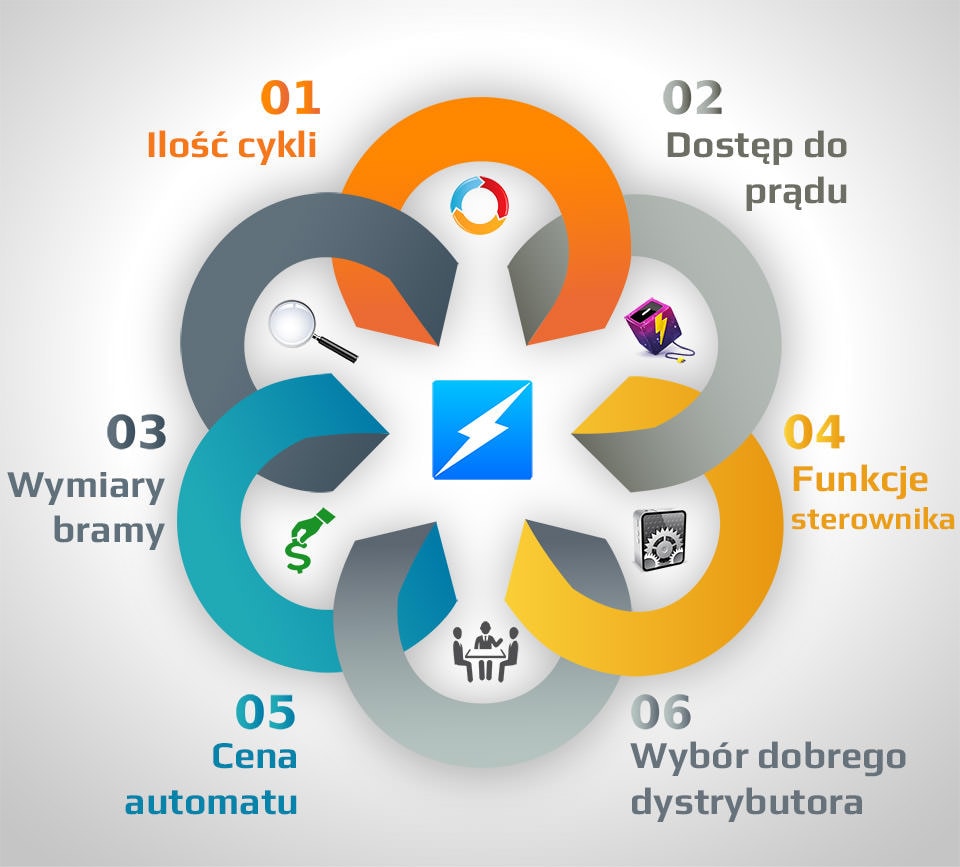

Jaki wybrać automat lub napęd do bramy?

Jaki wybrać automat lub napęd do bramy?

6 przydatnych odpowiedzi

Praktyczny poradnik napisany na bazie doświadczeń naszych klientów. Dowiesz się w nim na co zwracać szczególną uwagę podczas zakupu automatu dla Twojej bramy. Przeczytaj artykuł na blogu →

Działanie, budowa oraz zastosowanie siłownika elektrycznego

Jak działa siłownik elektryczny? Jaka jest jego budowa oraz zastosowanie?

Przeczytaj artykuł na blogu →

biuro@elektrobim.pl

biuro@elektrobim.pl 91 817 14 69

91 817 14 69